What should we pay attention to when welding steel grating?

Steel grating is a kind of steel product with square gr [...]

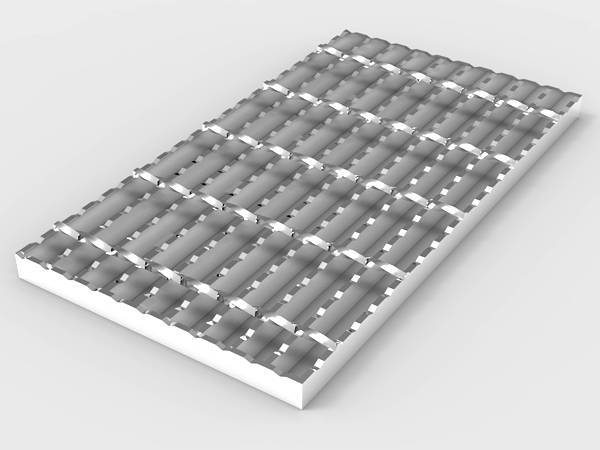

Steel grating is a kind of steel product with square grid in the middle, which is made of flat steel arranged at a certain spacing and cross bars, and welded by pressure welding machine or manually. Steel grating is mainly used for ditch cover, steel structure platform plate, steel ladder tread, etc. The cross bar is generally made of twisted square steel. Steel grating is generally made of carbon steel, and the surface is hot-dip galvanized to prevent oxidation. It can also be made of stainless steel. Steel grating has ventilation, lighting, heat dissipation, anti-slip, explosion-proof and other properties.

Welding Note:

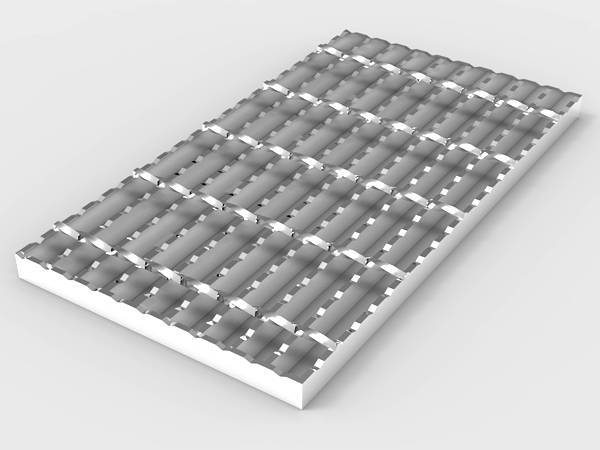

1. At each intersection of the load flat steel and the cross bar, it should be fixed by welding, riveting or pressing.

2. Pressure resistance welding is preferred for welding of steel grating, and arc welding can also be used.

3. The press lock of steel grating can use a press to press the cross bar into the load flat steel to fix it.

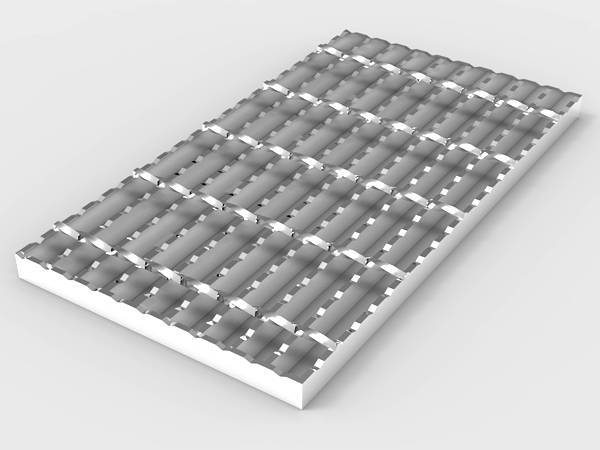

4. Steel grating should be processed into various sizes according to user needs.

5. The spacing of the load flat steel and the spacing of the cross bar can be determined by the supplier and demander according to the design requirements. For industrial platforms, it is recommended that the spacing between load flat steel bars should not be greater than 40mm and the spacing between cross bars should not be greater than 165mm.

Please login to write a comment after