US 8.99-9.99 / square meter

30 square metersMinimum order

Place of Origin:

Hebei, China

Material:

STAINLESS STEEL WIRE, ss304, ss316

Type:

Wire Cloth

Application:

Woven Wire Mesh

Weave Style:

Plain Weave

Technique:

woven

Quik Detail

| Place of Origin | Hebei, China |

|---|---|

| Material | STAINLESS STEEL WIRE, ss304, ss316 |

| Type | Wire Cloth |

| Application | Woven Wire Mesh |

| Weave Style | Plain Weave |

| Technique | woven |

| Model Number | yhy15xgcp |

| Brand Name | YHY |

| Processing Service | Bending, Welding, Cutting |

| Delivery Time | 15-21 days |

| Width | 0.5m, 1m, 1.2m, etc |

| Length | 30m per roll, etc |

| Mesh | 40mesh, 50mesh, 60mesh, 120mesh, 200mesh, etc |

| Certification | CE approved |

| Sample | Small piece for free |

| Market | USA, Boliva, Brazil, Korea, Vietnam, malaysia |

| Usage | Filter, Screen, etc |

| Edge | Raw edge, neat |

| Quantity | 5 rolls |

Product Detail

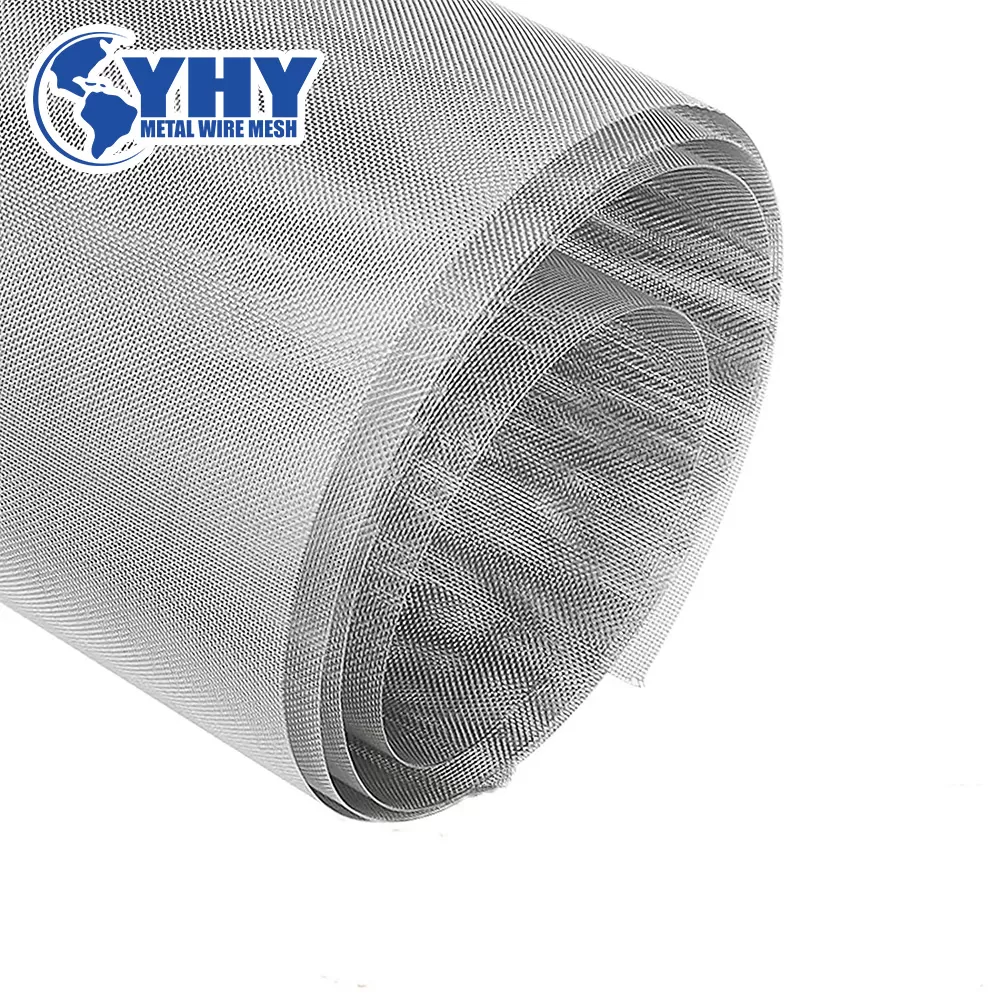

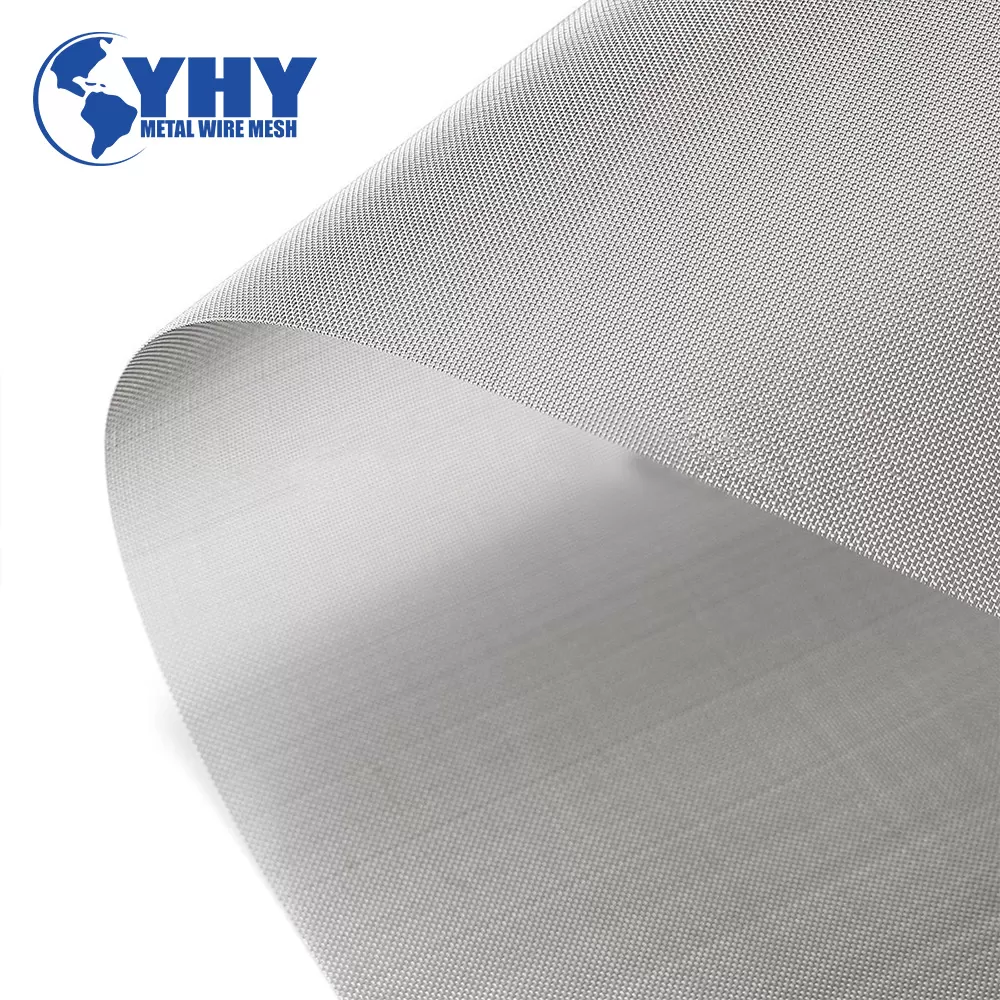

STAINLESS STEEL MESH

YingHangYuan Metal Mesh Industry

Stainless steel is selected for their wear-resisting, heat-resisting, acid-resisting and corrosion resisting characteristics. Many different grades of stainless are used in wire cloth.T304 is the most common, but other are used in specific applications to take advantage of each grade’s unique properties. The wire mesh made of stainless steel is extensively used in mining, chemical industry, food industry and pharmaceutical industry.

Knowledge of Stainless Steel Material

1. Mesh Count = 25.4mm/D+A

2. Aperture= 25.4mm/Mesh count – Diameter

3. % Open Area= A/(A+D)² X 100%

4. Micron= Aperture(mm) X 1000

5.Mesh – The number of openings per lineal inch.

6.Aperture- The distance between two adjacent wires

7.Diameter- The thickness of the wire before weaving

8.% Open Area- The ratio of the area of the aperture to the area of the 9.mesh expressed in percentage terms

10.Warp- All wires running lengthwise of the cloth as woven

11.Weft- All wires running across the cloth as woven

1. Mesh Count = 25.4mm/D+A

2. Aperture= 25.4mm/Mesh count – Diameter

3. % Open Area= A/(A+D)² X 100%

4. Micron= Aperture(mm) X 1000

5.Mesh – The number of openings per lineal inch.

6.Aperture- The distance between two adjacent wires

7.Diameter- The thickness of the wire before weaving

8.% Open Area- The ratio of the area of the aperture to the area of the 9.mesh expressed in percentage terms

10.Warp- All wires running lengthwise of the cloth as woven

11.Weft- All wires running across the cloth as woven

1.High finish, no surface treatment required, easy maintenance.

2.High temperature oxidation resistance, 316 stainless steel resistance temperature is 1700 degrees Celsius.

3.Acid resistance, alkali resistance, good corrosion resistance.

4.High strength, tensile strength, toughness and wear resistance, durable.

Anping Yinghangyuan Wire Mesh Co., LTD., founded in 2008.Is a professional production of wire mesh products enterprises. The annual output value exceeds 10 million yuan.

Quality control in our factory is very strict and we operate our factory according to iso9001:2015 standard. From raw materials, production, quality testing, packaging. Each process is tested by trained workers and records are kept in the company system.

The company has passed ISO quality management system certification, and constantly implement and improve. In order to ensure that employees have a safe and healthy working environment, our company has carried out and passed the safety production standardization and occupational hazard risk control system certification. The company adheres to the quality management policy of "excellence, zero defect", and integrates the quality consciousness and quality concept into every aspect of the company's operation.

According to customer requirements, provide different packaging.

1. Standard packing—Bulk. Save space, packaging costs, and shipping costs without using pallets.

2. Customized packing. The cost is high, but the loading and unloading is convenient, saving labor costs.

3. Custom labels.

Warehousing: Our factory has a large warehouse, which is clean and dry. A short-term storage screen service is available.

1. Standard packing—Bulk. Save space, packaging costs, and shipping costs without using pallets.

2. Customized packing. The cost is high, but the loading and unloading is convenient, saving labor costs.

3. Custom labels.

Warehousing: Our factory has a large warehouse, which is clean and dry. A short-term storage screen service is available.