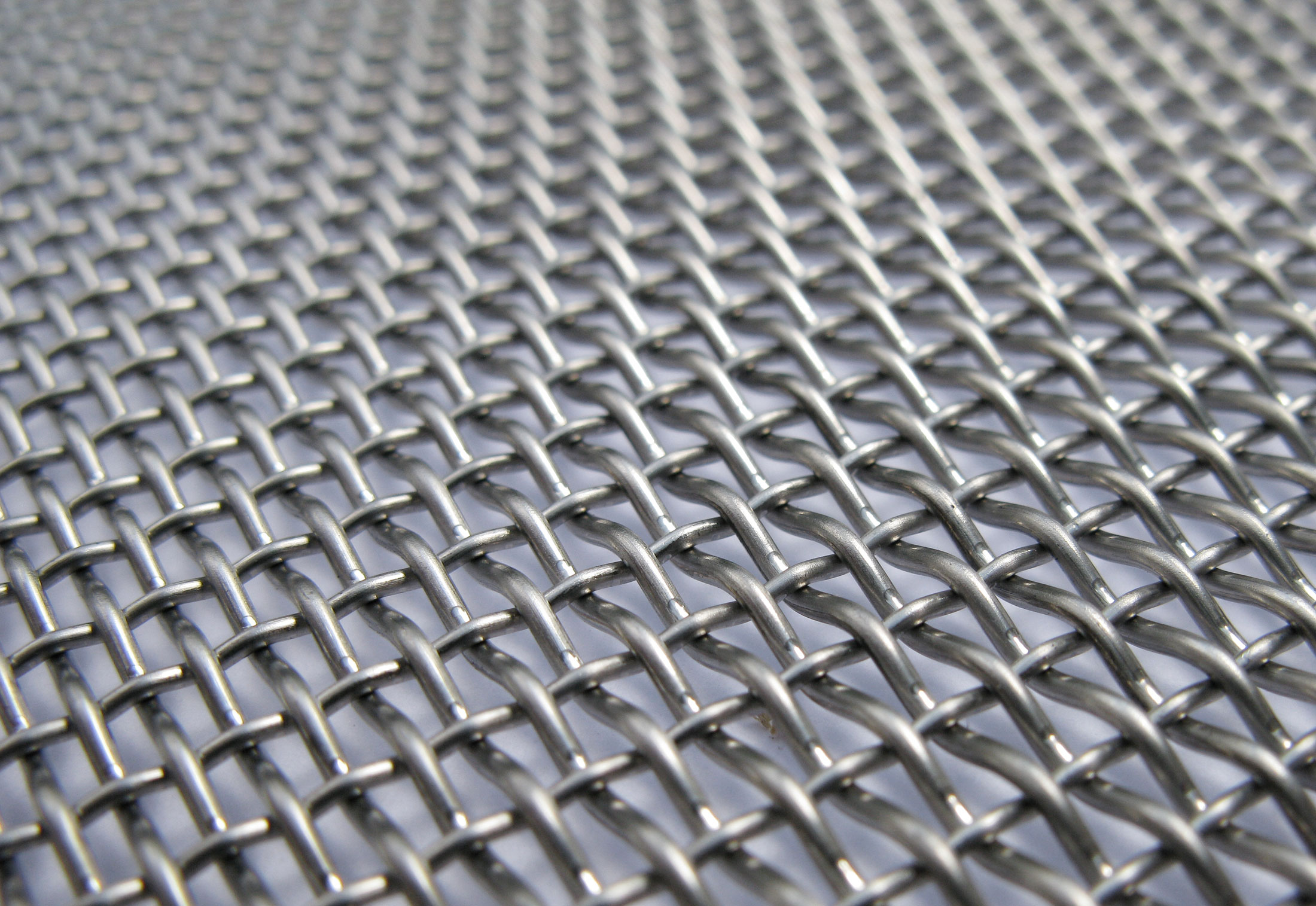

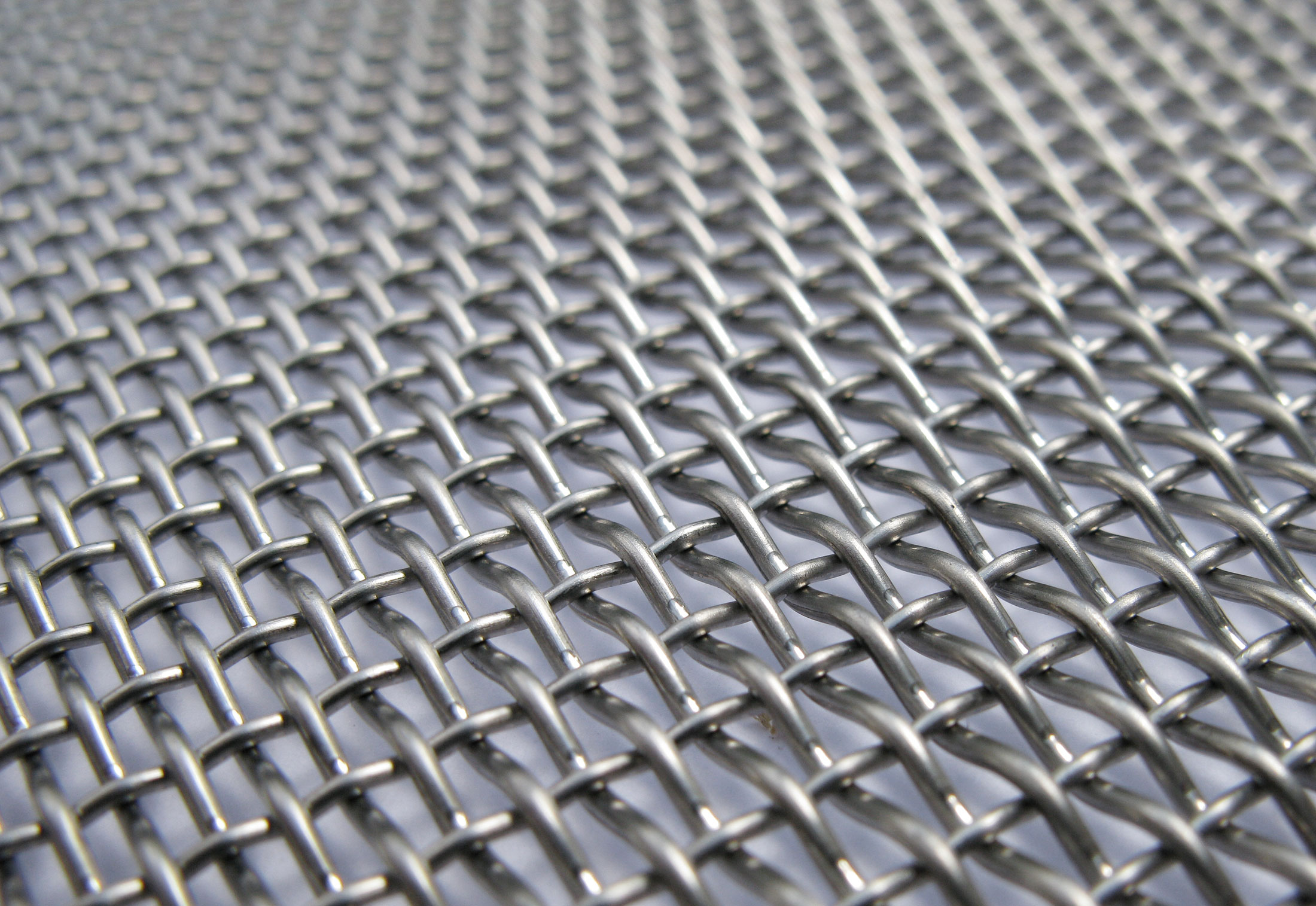

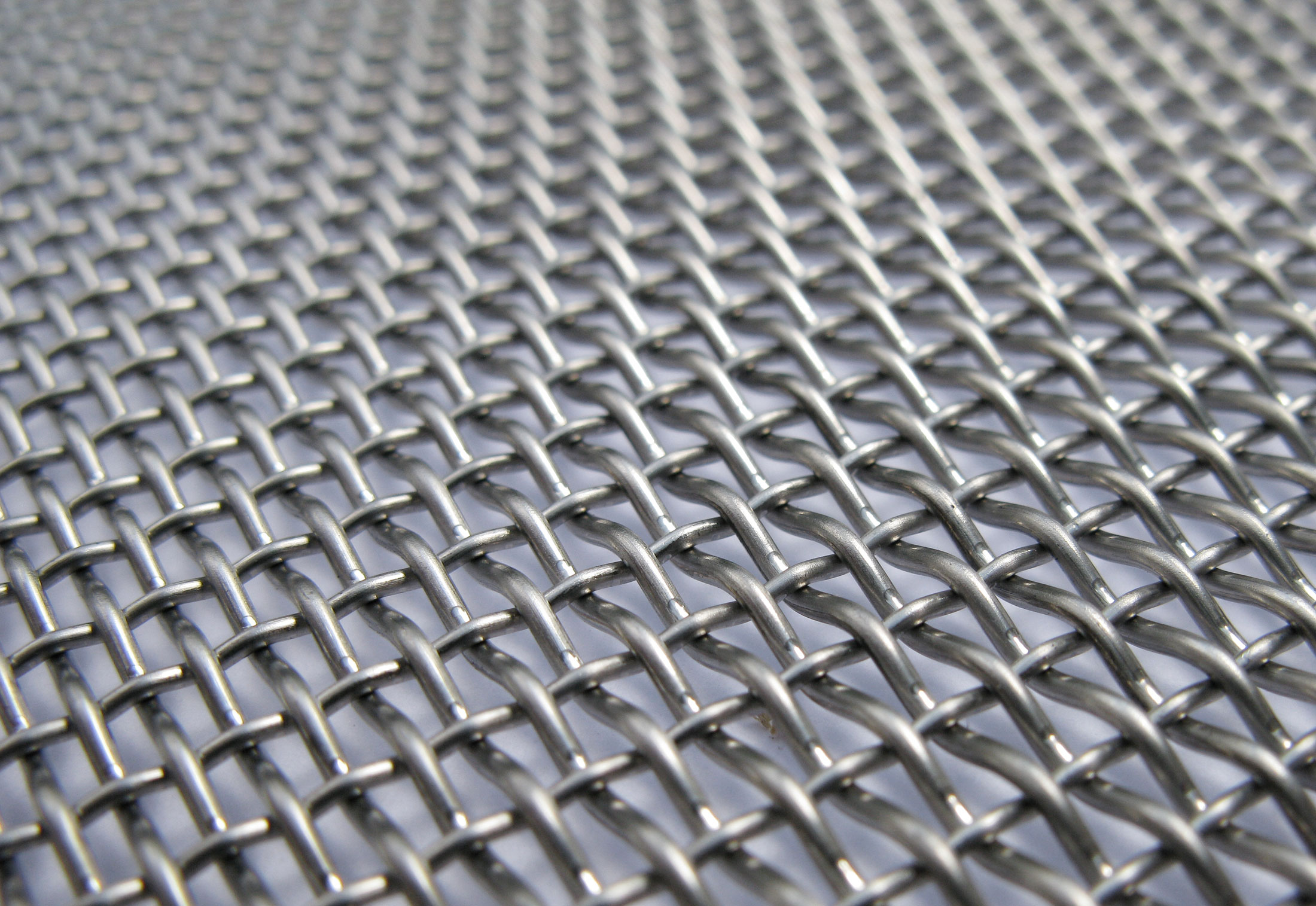

Stainless steel screen product specifications, types and uses

Stainless steel mesh is made of high-quality stainless [...]

Stainless steel mesh is made of high-quality stainless steel wire that is stretched to a specified wire diameter by a wire drawing machine under specific high-temperature process conditions, and then woven through a knitting machine in a constant-temperature, dust-free, clean factory.

Stainless steel screens refer to mesh products made of stainless steel materials such as stainless steel wires or plates.

Material: SUS201, SUS202, SUS302, SUS304, SUS316, SUS304L, SUS316L, SUS310, SUS310s, SUS430 and other stainless steel grades

Stainless steel screens are divided into three categories:

1. Plain stainless steel screen:

The most common braiding method is widely used in industrial production and civil life. Its main feature is that the density of the warp and weft wire diameters is the same.

2. Stainless steel square mesh

Material: galvanized iron wire, stainless steel wire, copper wire, aluminum wire, etc.

Features: Precise structure, uniform mesh, good corrosion resistance, strong and durable.

Widely used in industry and construction to screen sand and filter liquids and gases. It can also be used for safety protection of mechanical accessories, etc., and it can also be used to replace wooden strips to make walls and ceilings.

3. Stainless steel mat mesh/dense mesh

Material: stainless steel wire, low carbon steel wire, nickel wire, copper wire, polyester wire, etc.

Weaving: plain weave, twill weave, bamboo flower weave, contrast weave. Features: Good filtration accuracy, high load strength of contrast net.

Usage: Used in aerospace, petroleum, chemical industry, scientific research and transportation industries. It can also be used to make lunch box nets, coal washing nets, etc. Main uses of stainless steel screens:

1. Used for screening and filtration under acid and alkali environmental conditions. In the petroleum industry, it is used as a mud net, in the chemical and chemical fiber industry, as a screen filter, and in electroplating...

2 Used in mining, petroleum, chemical industry, food, medicine, machinery manufacturing and other industries. ...

3: Used for screening and filtration under acid and alkali environmental conditions, used as mud mesh in the petroleum industry, screening in the chemical fiber industry, and pickling mesh in the electroplating industry.

Please login to write a comment after