According to the scientific and reasonable design of th [...]

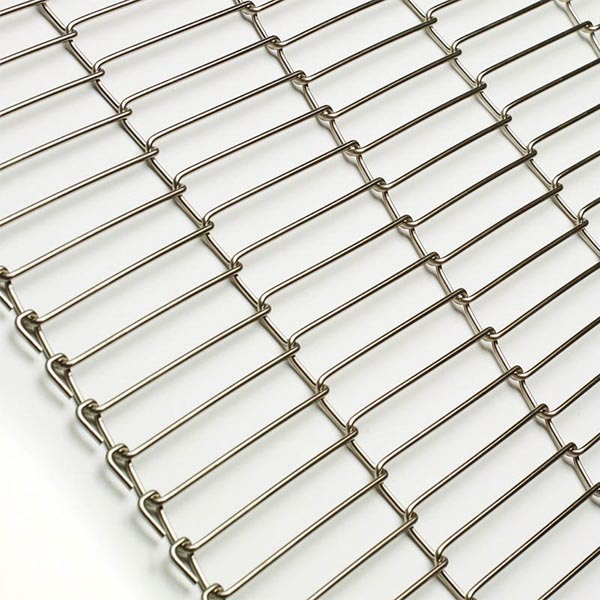

According to the scientific and reasonable design of the curved route of the stainless steel mesh belt, the H-frame of the fuselage of the overall conveyor is updated and transformed, so that the conveying equipment can complete the stainless steel mesh belt to change direction according to the designed curved route. At present, there are two kinds of stainless steel mesh belt methods, which are respectively mandatory direction-changing stainless steel mesh belt and stainless steel mesh belt changing direction stainless steel mesh belt. Mandatory direction change stainless steel mesh belt The stainless steel mesh belt design of forced direction change stainless steel mesh belt depends on not changing the main components of the original belt conveyor. It is necessary to add a corner station to the stainless steel mesh belt to carry out relevant rational design and installation. Then complete the stainless steel mesh belt, the angle of view of the stainless steel mesh belt is in the inclined well of 8-90 degrees. The stainless steel mesh belt is changed to the stainless steel mesh belt, which promotes the bending operation of the belt according to the structural regularity of the stainless steel mesh belt, that is, the non-mandatory stainless steel mesh belt. This stainless steel mesh belt method selects technical measures to obtain the radius of the stainless steel mesh belt through calculation, and paves according to this radius. The conveyor belt can be bent and run in the plane without deviation in direction. This type of stainless steel mesh belt has a simple structure and is conducive to maintenance. , suitable for inclined wells with small angle of view of stainless steel mesh belt.

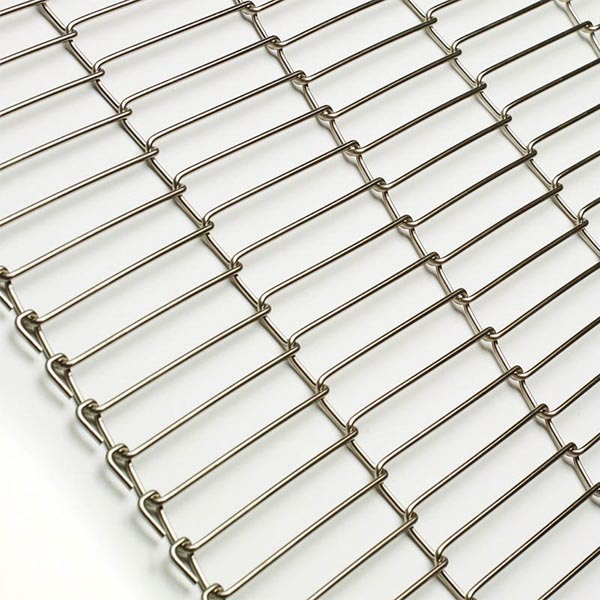

Due to the appearance of stainless steel mesh belt conveying equipment, most enterprises use this kind of conveying equipment. Along with the development trend of industrial production technology level, belt conveyors are also developing rapidly and innovating independently. Nowadays, stainless steel mesh belts, one of the belt conveyors, are also widely used in the production lines of various enterprises. the

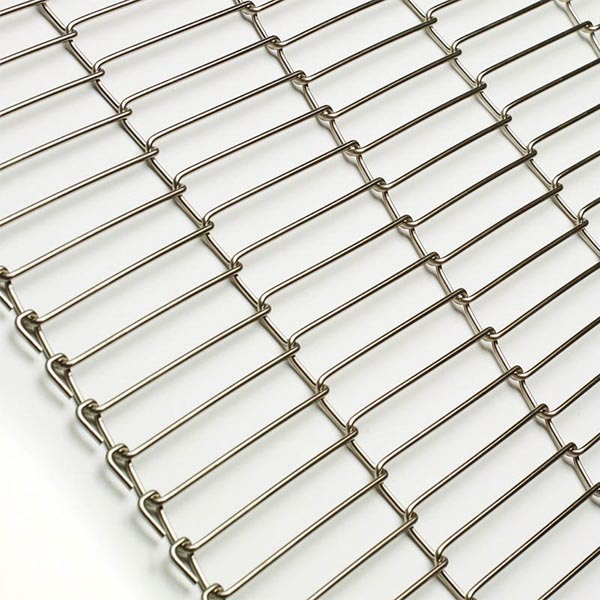

The stainless steel mesh belt equipment is a mechanical equipment with the same power transmission system, which reduces friction through the chain and makes the equipment more convenient. When the stainless steel mesh belt is eroded or corroded, it will cause damage to the stainless steel mesh belt: the stainless steel mesh belt is thin; the damage is accelerated. the

Rusting of components can lead to stainless steel mesh belt conveyor chains and soft turning rollers; stress corrosion and intergranular corrosion can occur. However, compared with the stainless steel mesh belt, it has obvious stainless steel mesh belt points, but the application of belt transmission in the facility is not suitable, mainly due to the problem of bearing capacity, and the stainless steel mesh belt does not have such a large load.

Please login to write a comment after